Found this summary of the 6.0L lube oil and high pressure oil system. Thought I would post it.

LPOP design flow 18.5 gpm (filter designed at 20 gpm).

The threaded port for the base oil pressure switch in the filter base isn't very deep and the threads can strip (or even crack the oil filter housing). An adapter fitting is available for a better/safer "fit"in the oil filter base, and also better fit for the sensor in the fitting.

www.accuratediesel.com

www.accuratediesel.com

The oil pressure switch engages at 5-7 psig to move the dash indicator to the mid zone (anything less than that will just show no oil pressure on the dash gauge).

12 psig at 700 rpm is minimum recommended, with the engine at operating temperature.

24 psig at 1200 rpm.

45 psig at 1800.

Oil pressure regulator opens at pressure of 75 psig to send flow back to the pump suction.

Sending unit threads: 7/16 - 20

The lubrication system is pressure regulated, cooled, and full flow filtered. In addition to providing engine lubrication, it supplies oil to the high-pressure oil system to control fuel delivery in the fuel injectors.

The following sequence describes lube oil flow through the major oil system components:

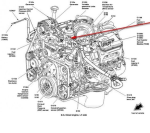

NOTE: the diagram below shows the '05 and up HPO system (identified by the HPOP).

![Image]()

![Image]()

The high-pressure oil system is composed of two subsystems:

The ICP system is composed of the following components:

The high-pressure oil pump is mounted at the rear of the crankcase and is driven by the camshaft gear. Oil is drawn from the oil reservoir through a 200-micron screen and into a passage to the pump inlet port. High-pressure oil from the pump is distributed to the injectors through a series of tubes and manifolds.

The high-pressure discharge tube is mounted to the pump and serves to connect the oil flow from the high-pressure oil pump to the rear engine tube assembly. This tube assembly divides oil flow into two tubes or branches, one for each side of the engine. Rigid tubes in each branch direct oil up into the high-pressure oil rail of each cylinder head. Oil from the rails enters the injectors through O-ring sealed ports at the top of each injector. When the injector opening coil is energized, high-pressure oil is used to push fuel into the combustion chamber. After injection is complete, the oil inside the injector is vented through the top portion of the injector and allowed to drain back to the oil sump.

![Image]()

LPOP design flow 18.5 gpm (filter designed at 20 gpm).

The threaded port for the base oil pressure switch in the filter base isn't very deep and the threads can strip (or even crack the oil filter housing). An adapter fitting is available for a better/safer "fit"in the oil filter base, and also better fit for the sensor in the fitting.

6.4 and 6.0 Powerstroke Oil Pressure Sensor Adapter

This 6.4 / 6.0 Powerstroke oil pressure sensor adapter is equipped with threads longer than those on the OEM sensor. Order this repair adapter today!

The oil pressure switch engages at 5-7 psig to move the dash indicator to the mid zone (anything less than that will just show no oil pressure on the dash gauge).

12 psig at 700 rpm is minimum recommended, with the engine at operating temperature.

24 psig at 1200 rpm.

45 psig at 1800.

Oil pressure regulator opens at pressure of 75 psig to send flow back to the pump suction.

Sending unit threads: 7/16 - 20

The lubrication system is pressure regulated, cooled, and full flow filtered. In addition to providing engine lubrication, it supplies oil to the high-pressure oil system to control fuel delivery in the fuel injectors.

The following sequence describes lube oil flow through the major oil system components:

- Oil pan (sump).

- Oil pickup tube and screen.

- The low pressure oil pump is a gerotor type contained in the front cover. The gerotor assembly consists of an outer and an inner gear. The inner gear is driven by the crankshaft. The pump inlet and outlet passages are through ports in the front cover.

- Oil pressure regulator (bypass) controls lube oil pressure via a spring-loaded plunger relieving oil back to the inlet of the pump once operating pressure has exceeded 517 kPa (75 psi).

- The oil cooler cover receives oil from the oil pump and cools it in the oil cooler, which is located underneath the oil cooler housing.

- The cooler bypass valves open in the event that the oil cooler base and/or cooler becomes restricted.

- The oil filter housing contains a paper-type element. Unfiltered oil flows up and around the outside of the filter and then down through the center standpipe.

- The oil filter bypass allows oil to pass directly to the main oil gallery should the filter become restricted.

- Turbocharger and drive gears.

- Cooled and filtered oil supplied from the oil cooler base lubricates the turbocharger bearings and provides hydraulic pressure for the variable geometry turbocharger control valve. Oil drains from the turbocharger through a drain tube back to the high-pressure hydraulic pump cover.

- Main galleries. Cooled and filtered oil supplied from the oil cooler base fills the main galleries to distribute oil to the following components via passages machined within the crankcase.

- Hydraulic cam followers.

- Camshaft main journals.

- Crankshaft main journals.

- Connecting rod bearings receive pressurized oil from the main bearings via drilled passages within the crankshaft.

- Rocker arms receive their lube oil from the hydraulic cam followers via the push rods. Oil drains back to the sump through holes located in the cylinder head.

- Piston cooling tubes.

- High-pressure hydraulic pump oil reservoir.

- This reservoir (below oil cooler) has a constant supply of oil for the pressure hydraulic oil pump. It has an approximate capacity of 0.9 L (0.95 qt).

NOTE: the diagram below shows the '05 and up HPO system (identified by the HPOP).

| Item | Part Number | Description |

|---|---|---|

| 1 | 6A638 | Crankcase oil cooler cover with oil cooler |

| 2 | 9G440 | Turbocharger oil supply tube |

| 3 | 6K682 | Turbocharger |

| 4 | 6565 | Push rod |

| 5 | 6500 | Valve tappet |

| 6 | - | Main lube oil galleries (part of 6010) |

| 7 | 9A543 | High-pressure oil pump |

| 8 | - | Camshaft gear (part of 6250) |

| 9 | 6C327 | Piston cooling jet |

| 10 | 6333 | Main bearings |

| 11 | 6049 | Cylinder head |

| 12 | 6676 | Lower oil pan |

| 13 | 6622 | Oil pickup tube |

| 14 | 6019 | Front cover assembly |

| 15 | 6608 | Oil pump drive rotor and shaft assembly |

| 16 | 6616 | Oil pump body |

| 17 | 6A251 | Camshaft bushing |

| 18 | 6B678 | Oil pressure regulator valve assembly (part of 6019) |

| Item | Part Number | Description |

|---|---|---|

| 1 | 9D280 | Fuel injector manifold assembly |

| 2 | - | Crankcase-to-head tube assembly (late build) |

| 3 | 9A332 | Crankcase-to-head tube (early build) |

| 4 | 9J332 | Rear engine tube assembly |

| 5 | 9C968 | Injection pressure regulator valve |

| 6 | 9A543 | Fuel injector pump assembly |

| 7 | 6L080 | Engine rear cover assembly |

| 8 | 6701 | Crankshaft rear oil seal assembly |

| 9 | 6D083 | Engine rear cover gasket |

| 10 | 6010 | Cylinder block assembly |

| 11 | 6020 | Cylinder front cover gasket |

| 12 | 8575 | Water thermostat assembly |

| 13 | 6019 | Cylinder front cover assembly |

| 14 | 6608 | Oil pump drive rotor and shaft assembly |

| 15 | 6616 | Oil pump body |

| 16 | 6700 | Crankcase front oil seal |

| 17 | 6316 | Crankshaft vibration damper |

| 18 | 8509 | Water Pump pulley assembly |

| 19 | 8501 | Water pump assembly |

| 20 | 6A638 | Crankcase oil cooler cover with oil cooler |

| 21 | 6881 | Oil filter adapter assembly |

| 22 | 6L625 | Engine oil filter and adapter assembly |

| 23 | 6718 | Oil filter outlet tube assembly |

| 24 | 6714 | Oil filter assembly |

| 25 | 6C631 | Oil filter cap assembly |

| 26 | 9F838 | Injection control pressure (ICP) sensor |

| 27 | 9E527 | Fuel injector nozzle assembly |

| 28 | 6095 | Fuel pump cover |

The high-pressure oil system is composed of two subsystems:

- Injection control pressure (ICP) system

- Fuel injector assembly

The ICP system is composed of the following components:

- Oil reservoir

- Oil Pump assembly (high pressure)

- Oil pump cover

- High-pressure tubes

- High-pressure rail assemblies

- Injection control pressure (ICP) sensor

- Injection pressure regulator (IPR) valve

- Check valves

The high-pressure oil pump is mounted at the rear of the crankcase and is driven by the camshaft gear. Oil is drawn from the oil reservoir through a 200-micron screen and into a passage to the pump inlet port. High-pressure oil from the pump is distributed to the injectors through a series of tubes and manifolds.

The high-pressure discharge tube is mounted to the pump and serves to connect the oil flow from the high-pressure oil pump to the rear engine tube assembly. This tube assembly divides oil flow into two tubes or branches, one for each side of the engine. Rigid tubes in each branch direct oil up into the high-pressure oil rail of each cylinder head. Oil from the rails enters the injectors through O-ring sealed ports at the top of each injector. When the injector opening coil is energized, high-pressure oil is used to push fuel into the combustion chamber. After injection is complete, the oil inside the injector is vented through the top portion of the injector and allowed to drain back to the oil sump.

| tem | Part Number | Description |

|---|---|---|

| 1 | 9A543 | Fuel Injector Pump assembly |

| 2 | 9C968 | Injection pressure regulator (IPR) valve |

| 3 | 6095 | Fuel pump cover |

| 4 | 9E527 | Fuel injectors (8 required) |

| 5 | 9D280 | Fuel injector manifold assembly (right side) |

| 6 | 9F838 | Injection control pressure (ICP) sensor |

| 7 | - | Crankcase-to-head tube assembly (right side) |

| 8 | 9J332 | Rear engine tube assembly |

| 9 | - | Crankcase-to-head tube assembly (left side) |

| 10 | 9D280 | Fuel injector manifold assembly (left side) |