I have now read several times that people repeatedly have problems with new Ford dummy plugs and standpipes.

Maybe the manufacturer used inferior o-rings for cost reasons?

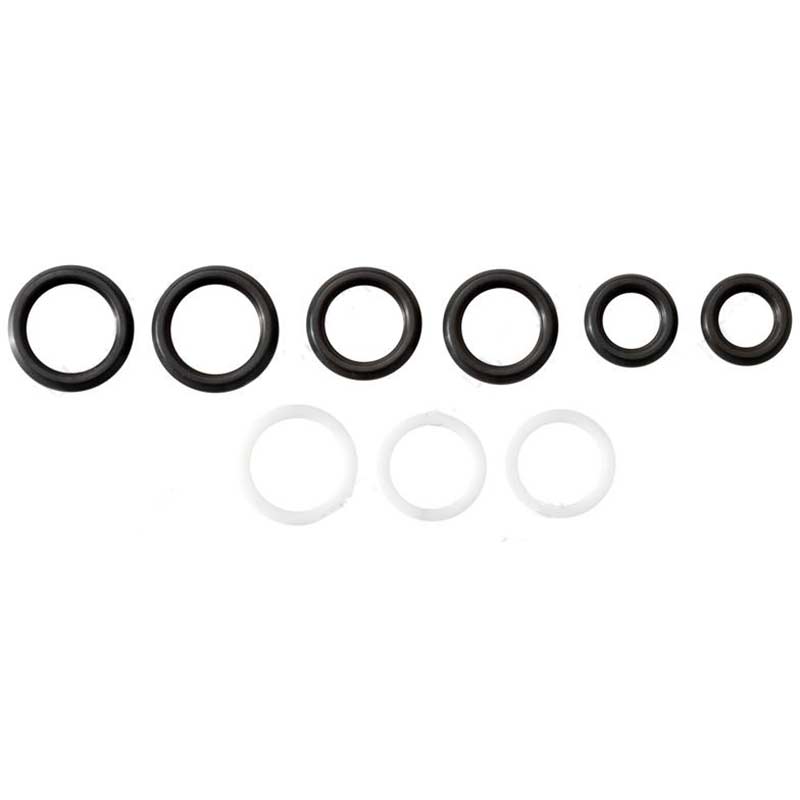

In principle, you would only have to replace the o-rings with ones made of high-quality material.

Has anyone already done this and measured the o-rings?

Maybe the manufacturer used inferior o-rings for cost reasons?

In principle, you would only have to replace the o-rings with ones made of high-quality material.

Has anyone already done this and measured the o-rings?