well over christmas holiday i fabbed up my traction bars.

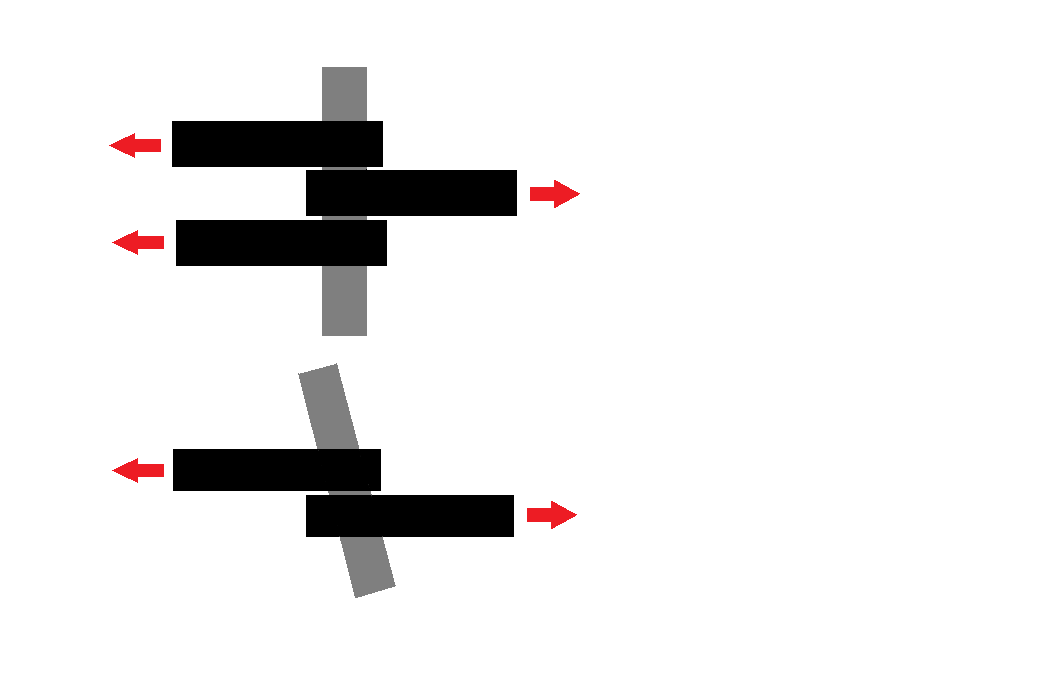

i looked at a lot out there and most have a fixed point where they attach to the frame. this is bad as it binds up the suspension travel of the suspension by trapping the bars and not allowing the hypotenuse of the triangle to move freely.

This Fabtech design was the best i saw and takes this binding into account with a swivel at the forward end of the bars.

https://www.amazon.com/gp/product/B000CMGXW0/ref=pe_58340_267052970_em_1p_0_ti

I got them installed and thus far seem to werk well.

The Fabtech set up is almost 800 bucks!!

I did mine for under 100 and am happy with how they perform.

I plan to add some more bracing in the middle. Currently I have (2) vertical struts, I will be adding (2) diagonals on either side of the verticals but I attached a pic of the setup.

I am pretty pleased.

i looked at a lot out there and most have a fixed point where they attach to the frame. this is bad as it binds up the suspension travel of the suspension by trapping the bars and not allowing the hypotenuse of the triangle to move freely.

This Fabtech design was the best i saw and takes this binding into account with a swivel at the forward end of the bars.

https://www.amazon.com/gp/product/B000CMGXW0/ref=pe_58340_267052970_em_1p_0_ti

I got them installed and thus far seem to werk well.

The Fabtech set up is almost 800 bucks!!

I did mine for under 100 and am happy with how they perform.

I plan to add some more bracing in the middle. Currently I have (2) vertical struts, I will be adding (2) diagonals on either side of the verticals but I attached a pic of the setup.

I am pretty pleased.